855-240-6776

Voltage Correction.com

All Things Voltage Correction, Conditioning and Industrial UPS Systems

Solving Your Facility Power Quality Issues

Incoming Utility Power Sags & Interruptions

Small Cycle Interruptions of Process Controls

Extended Power Interruption

Manufacturing Power Quality Issues Derived from Inside a Plant

Relevant Topics

Power Assessments and System Sizing

Small Single phase loads, or large medium voltage UPS System Sizing requires and understanding of the customer Equipment needing protection, and the amount of power equipment uses. We have integrated Power Assessment Processes that can take customer's through, step-by-step, to examine the equipment, loads, and the sizing of systems to remedy Site Power Issues.

Voltage Regulators and Conditioners

1kVA-5000kVA-10MVA

Voltage Conditioning and Correction for various voltage sterilization requirements. 1kVA- 60MVA

Single Phase UPS Systems

500VA-20kVA

Point-of-Sale, desktop, and network UPS

Both Lithium ION and VRLA battery

Low/Medium Voltage UPS Systems

10kVA-40MW

3-Phase UPS, Medium Voltage UPS, Large Scale Industrial Systems, 208v, 480v, 3.6kV, 34.5kV

Medium Voltage UPS Systems

Medium Voltage UPS Systems provide efficient delivery of high voltage power closer to rack loads. Subsequently changing the efficiency profile of the Power Distribution, and Reducing amounts of components and Interconnect wiring. New Demand Designed Chips require high density power integration to rack rows in the form of 100kW per rack, 200kW per rack, and 300kW per rack. AI processing and compute requires the most efficient power delivery mechanisms.

WHY CHOOSE FGC Equipment/Services?

The Customer Experience

FGC Asset Management Software - Asset / Portfolio Tracking

Roll all your Critical Assets and Maintenance Programs into one location - Facility Keys Preferred Platform

Log historical maintenance and repair data, view current calendar of maintenance activities, manage and control Asset Lifecycle. Budgeting, Billing, Reporting all in one easy location.

7 x 24 FGC Emergency Service Response

24x7 emergency service Services through FGC Services and Response Platform, 7x24 NOC.

Preventative Maintenance Plans Provided by FGC Services

Keep all your systems free of downtime with Preventative Maintenance Programs.

Plans include Full Service, Preventative Maintenance Plus Emergency Response, and PM Only.

Parts coverage inside your warranty period, extended plans available for Annual or Multi-Year Programs

FGC Comprehensive Services - Your Partner in Business

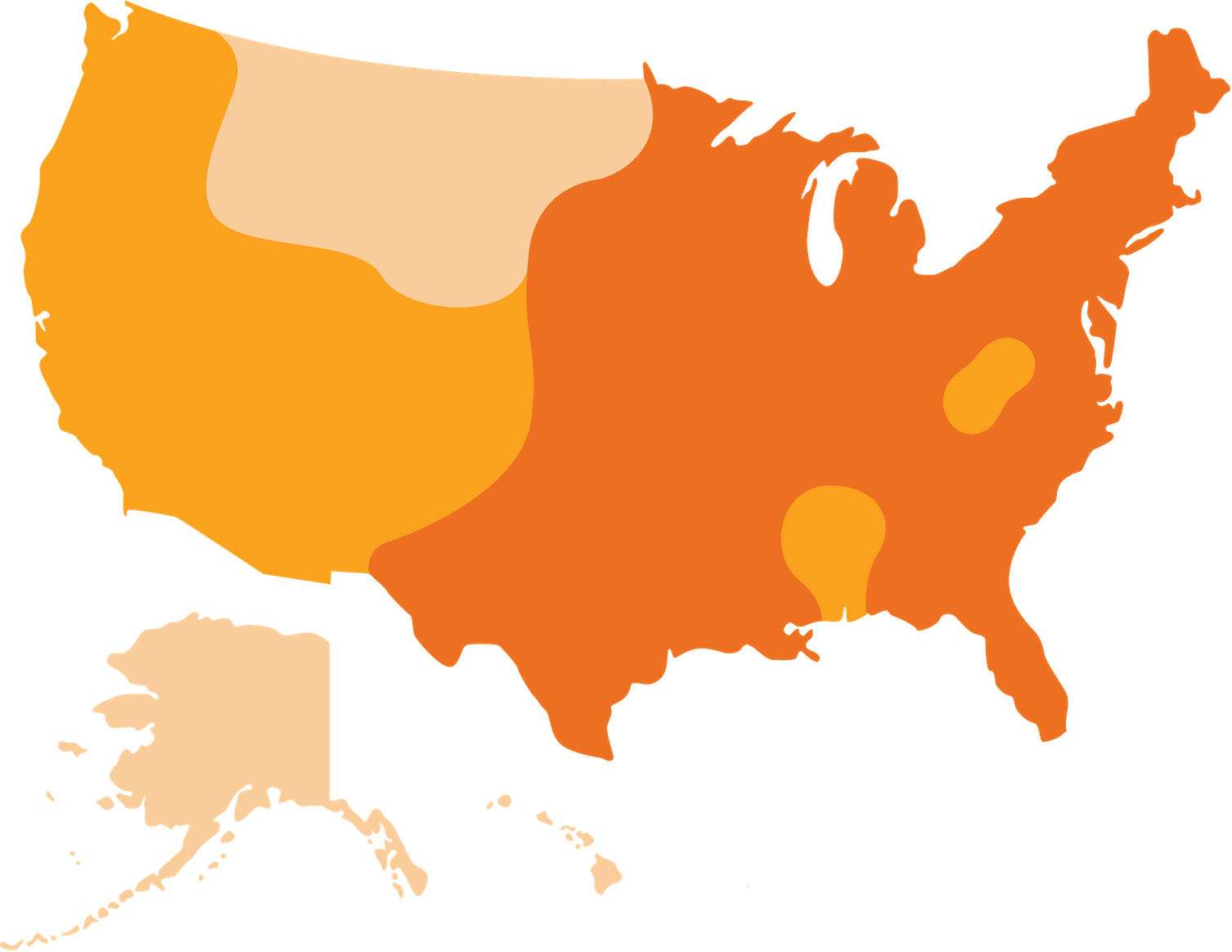

FGC is a 20 Year Nationally Recognized Distributor and Service Provider for Critical UPS Systems, and Battery Services. National Equipment Sales coverage in the Continental US States, National Service Coverage in the Continental US States. Your trusted Partner for all Critical Equipment, Technical Services, or Installation needs.

FGC 7x24 Emergency Response / Repair UPS

FGC National Service Coverage for Emergency Calls, On-Site Response, and Remediation.

ADDITIONAL FGC EQUIPMENT SERVICES

On Site Power Studies - Utility Bill Calculations - UPS Sizing Assistance - UPS Electrical Planning - UPS Installation Planning - Battery Runtime

Voltage Swell Questions - Voltage Sag Issues - Facility Electrical One Line Review - Power Study Reports - Metering - Turn-Key Installation

Plant and Process Equipment Protection - PLC Controls Power Protection - Process Interruption Issues

UPS - Battery - Generator - Switchgear - HVAC

Submit an RFP

It’s important to know how to size your UPS. Whether single or three-phase, there are several important factors to consider when correctly sizing your UPS system. At any time you can consult our Technical Consultants to help you with this via chat, call, or email. We discuss your situation and recommend an appropriate system.

RFP Initial CTA Homepage

We will get back to you as soon as possible.

Please try again later.

What is a UPS and How Does it Work?

Definition: Uninterruptible Power System

Use: Depending on the Technology, a UPS provides power conditioning while under normal operation. In the event of a power outage or extreme power sag, the UPS will provide power to the protected loads from it's battery source.

Technologies:

A -Single Conversion: Pass through voltage, responsive correction

B -Line Interactive: Bucks and Boosts Voltage normally

B -Double Conversion:

100% power creation, AC to DC, DC to AC

Contact Us

We Can Help Answer Any Unanswered Questions

Experienced Product Representatives are on hand to send you information and quotations for equipment. If you need help with sizing, installation planning, or general questions about products, please fill in the appropriate form below and someone will contact you shortly.

You may also call 844-501-1887 to get a direct product representative. Or you may chat with one of our product specialists in the chat box provided.

Homepage Footer Contact Form

We will get back to you as soon as possible.

Please try again later.